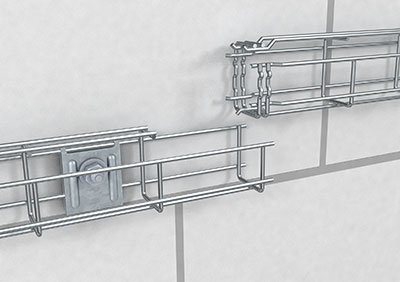

The system for direct wall and ceiling mounting

The G-shaped Magic mesh cable tray with moulded connector made of spot-welded steel wire allows direct wall and ceiling mounting. The clever plug connection of the mesh cable tray helps save time during mounting. With a wide selection of materials, the Magic G mesh cable tray can be used in a variety of installation environments and can also meet challenging requirements. The G-GR-Magic is available in four side heights: 50 mm, 75 mm, 125 mm and 150 mm.

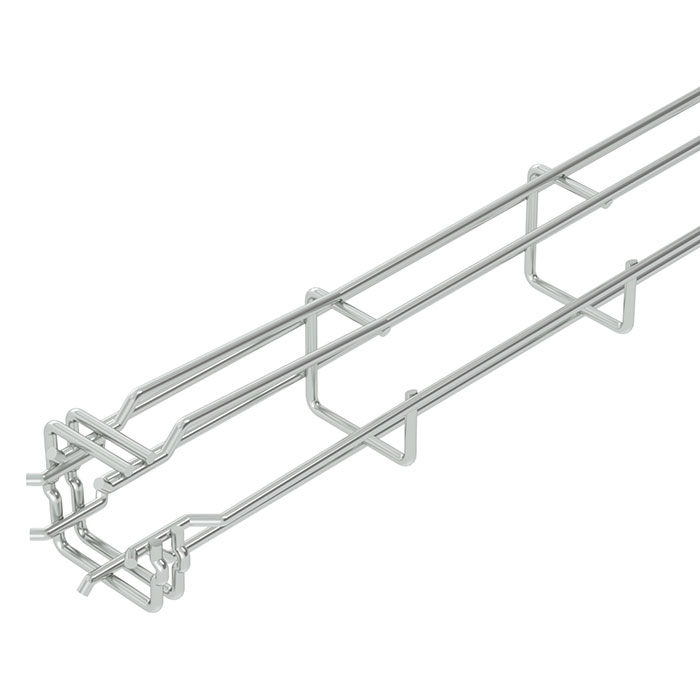

| Side height 50 mm |

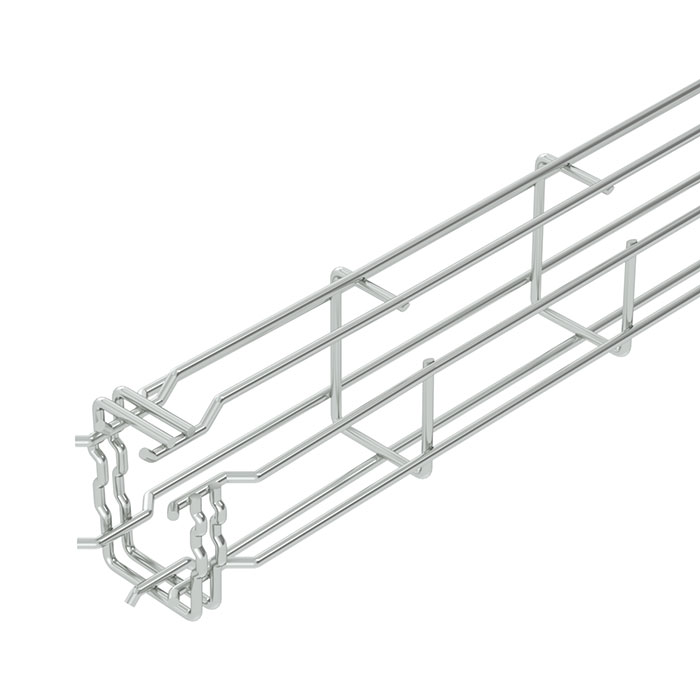

| Side height 75 mm |

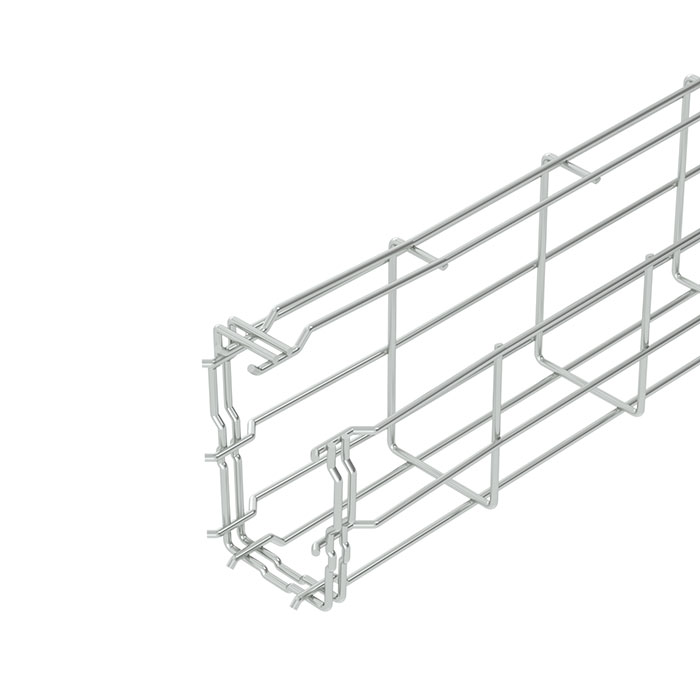

| Side height 125 mm |

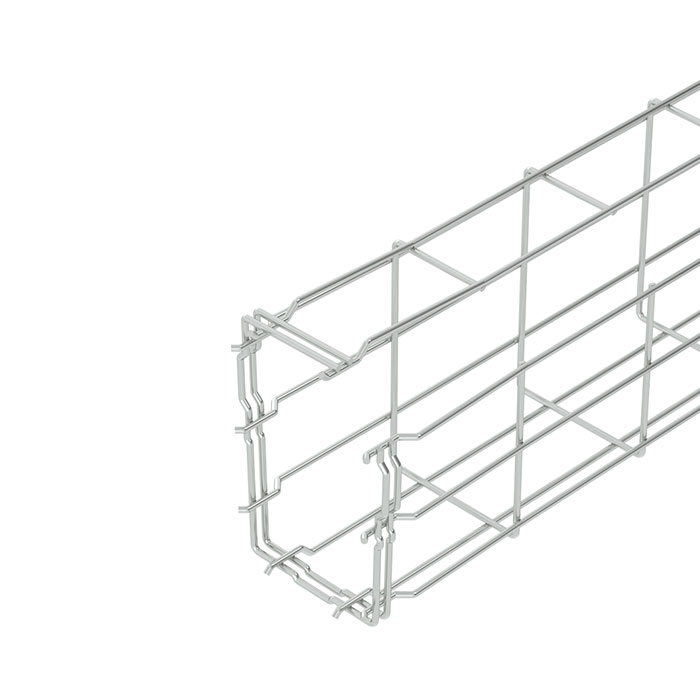

| Side height 150 mm |

Optimum room usage

Even if space is tight, the Magic® G mesh cable tray can be mounted almost anywhere. It can be attached directly to walls and ceilings in almost any position. The mesh cable tray can thus offer optimum cable routing in false ceilings, server rooms and office buildings. Another benefit is screwless working, thanks to the plug connection.

Innovative plug connection

The name already says it: The Magic® G mesh cable tray possesses the innovative Magic plug connection, developed by OBO engineers. The mesh cable tray system is simply connected, engaged – and you're done. Without screws, connectors or other accessory parts, you can increase the mounting speed noticeably and effectively.

Mesh cable tray system with wide range of materials

In dry rooms, wet rooms, outdoor areas, in the food industry or in tunnel construction – each of these installation environments places very different demands on the products used there. This is no problem for the G-GR-Magic – it has the right surface for every area. The product range runs from electrogalvanised through hot-dip galvanised right through to stainless steel variants. The electrogalvanised variants are particularly suitable for use in indoor areas, the hot-dip galvanised mesh cable trays can also be used with ease in outdoor areas and the stainless steel variants can also meet the demands of industrial areas with high levels of humidity and an aggressive atmosphere, as well as the requirements of the food industry or the chemicals and pharmaceuticals industry.

| Coating thickness |

Standards |

Location of use |

| Electrogalvanisation (G) |

| Average value approx. 2.5–10 μm |

Electrolytic galvanisation |

Indoor areas |

| Hot dip galvanisation (FT) |

| Average value approx. 40–60 μm |

Hot galvanisation using the dipping method |

Outdoor areas |

| Stainless steel (A2) |

Designations |

Specifics

|

Location of use |

| Stainless steel (A2) |

European material number: |

Welded components are passivated |

Industrial areas with high levels of humidity and an aggressive |

| Stainless steel (A2) |

European material number: |

Welded components are passivated |

Industrial areas with high levels of humidity and an aggressive |

For OBO, safety is of paramount importance

The quality of the OBO mesh cable tray systems is tested in the in-house BET Test Centre. Here, they are tested for their maximum load capacity, carrying capacity and resistance to corrosion. The in-house testing system was specially constructed for the testing of OBO cable support systems. For example, the tests required by DIN EN 61537 can be carried out here. These prove the safe working load (SWL) and therefore a reliable carrying capacity of the systems.